Lumber has traditionally been graded by visual inspection based on visual observation of such characteristics as:

A second grading system, machine-stress rated [MSR] lumber is also used sorting the lumber into grades.

Lumber may be graded for visual and/or structural applications. Material for millwork (doors, windows, etc.) may specify grain orientation and clarity. While these grades may also serve as an indicator of structural capabilities, more often than not these higher grades are separated from structural lumber and sold to higher value purposes.

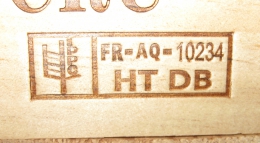

Lumber grades must follow standards set by organizations in the country of origin of the material.

In the United States, rules for grading are established by the U.S. Department of Commerce and maintained by the American Lumber Standard Committee. These standards are enforced by regional organizations (ie. Western Wood Products Association, Northeastern Lumber Manufacturers Association, Southern Pine Inspection Bureau, West Coast Lumber Inspection Bureau, and others).

In Canada, the Canadian Lumber Standards Accreditation Board (CLSAB), is the official body that monitors the quality of Canada’s lumber grading and identification system.

Lumber grading specifications and requirements between the two countries are largely aligned to ensure functional capabilities are met.

Wood is graded for its first use, and if it is to be reused in a structural capacity it will need to be either re-graded, or evaluated by a structural engineer for current structural capacity. Wood can be used for non-structural purpsoses, such as kneewalls or stud partition walls, without being graded.

You have no items in your list.

Click or tap on the My List stars on any business card or profile to add or remove organizations.